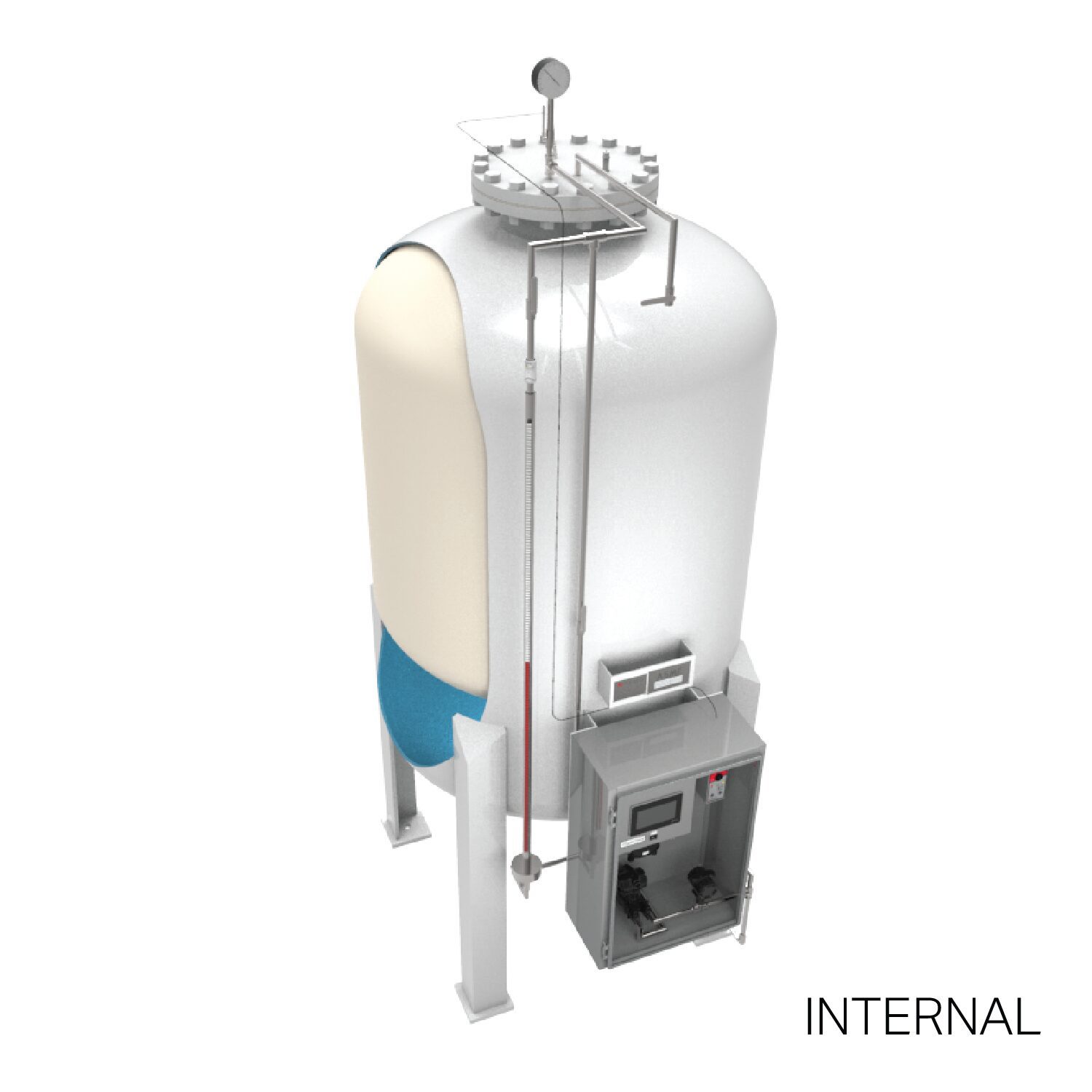

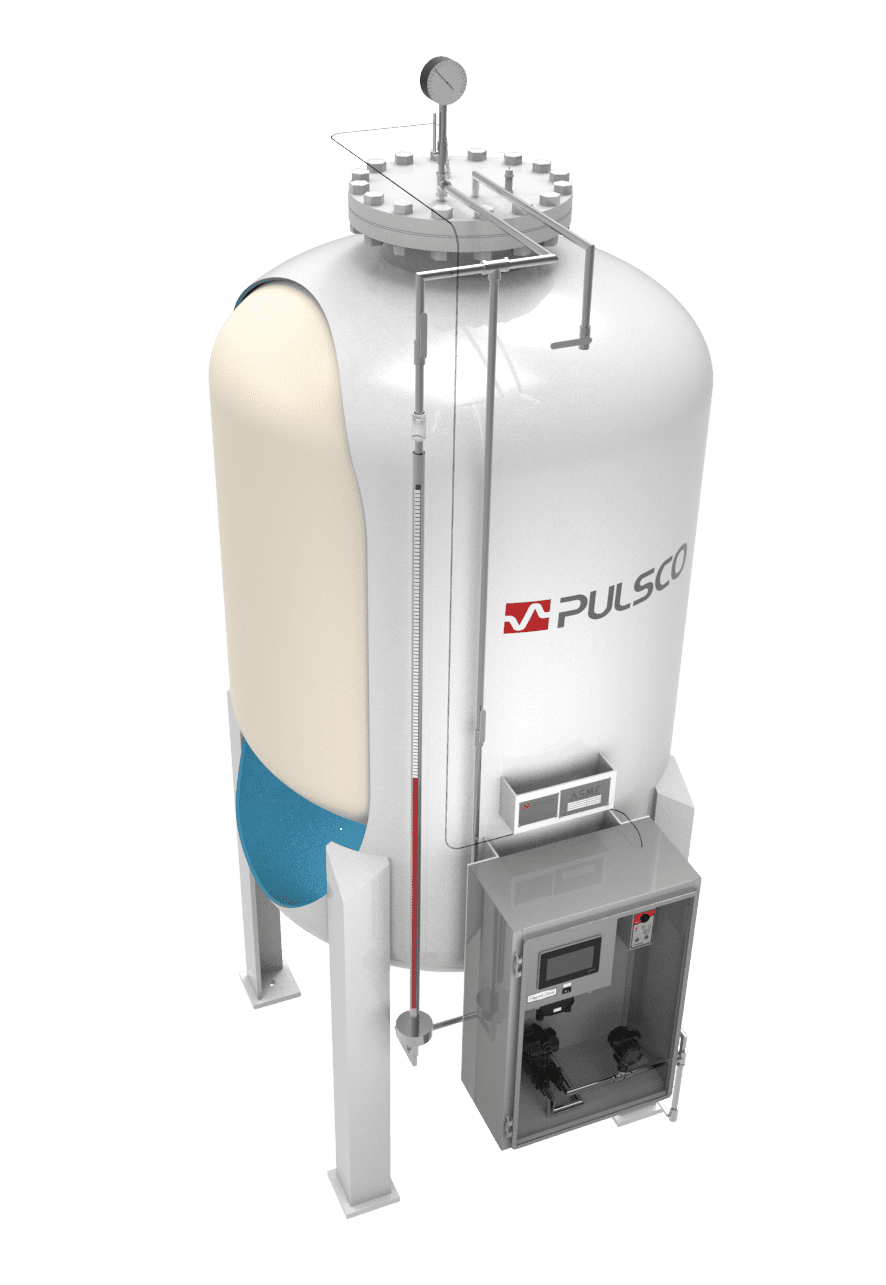

BPT-735

Bladder Pressure Control System

The Bladder System provides superior pressure protection for industries processing potable, raw, wastewater and hydrocarbons. The advantage of this system is the physical separation between the water and compressed air which eliminates the need for level controls. These pressure systems increase the life of your system and save the cost of electro-energy to drive the large pumps.

PULSCO’s Hydropneumatic Bladder Pressure Control System designs are developed from a proprietary program developed especially for pressure control analysis to model the fluid system and offer a low cost alternative for small water system application. From this analysis, the correct pressure tank and components can be sized and determined. The result is a complete and accurate account of system requirements and a reliable solution design for any transient flow problem.

The tank is designed, built and certified to ASME Sec. VIII, Div. 1 requirements. The tank volume and design pressure is determined by the system’s requirements and horizontal or vertical arrangements are possible with capacity ranging from 120 to 8,000 gallons, or to customer specification. The bladder is a heavy Elastomer which is chosen specifically for the application: potable water, raw, water or hydrocarbons. An optional PULSCO Bladder Failure Alarm provides local and remote alarm indication for a ruptured bladder.

The Bladder Pressure Control System produces frequent pump starts and stops during periods of peak service.

The principal components of the system are the ASME tank, bladder, safety valve, pressure gauge assembly and air charging valves.

Bladder Pressure Control System Components

Pressure Vessel

Pressure Relief Valve

Preinstalled Bladder, NSF

Antiextrusion Screen

Drain

Stainless Steel NPT Connections

Magnetic Level Indicator

1 inch stainless steel local visual indication recommended for ease of precharge

Differential Pressure Transmitter

Transmitter provides local and remote level indication

Pressure Gauge

2.5 inch dial pressure gauge, liquid filled

Pressure Transmitter

Transmitter provides local and remote pressure indication

Skypark 730

Two-analog and four-digital outputs NEMA 4 with 7 inch HMI touch screen interface

Ethernet TCP/IP communication standard

Bladder Monitoring Device

Provides continuous, real-time, safe monitoring of the bladder’s integrity

Enclosure

Skypark 730 and complete level control assembly is delivered prepiped and wired inside the NEMA 12 enclosure

Default Color: Gray