PULSCO has been designing and manufacturing industrial grade acoustic silencers to meet customers’ specific requirements for over 50 years. Our solutions for noise attenuation have been known to last for decades ensuring safe working environments, high-productivity, and decreased capital expenditure.

Noise Control Problem

The first step in finding a noise control solution is understanding the problem.

Design Inputs

There are a number of inputs that we require to design the best possible solution for you.

Silencer Type & Design

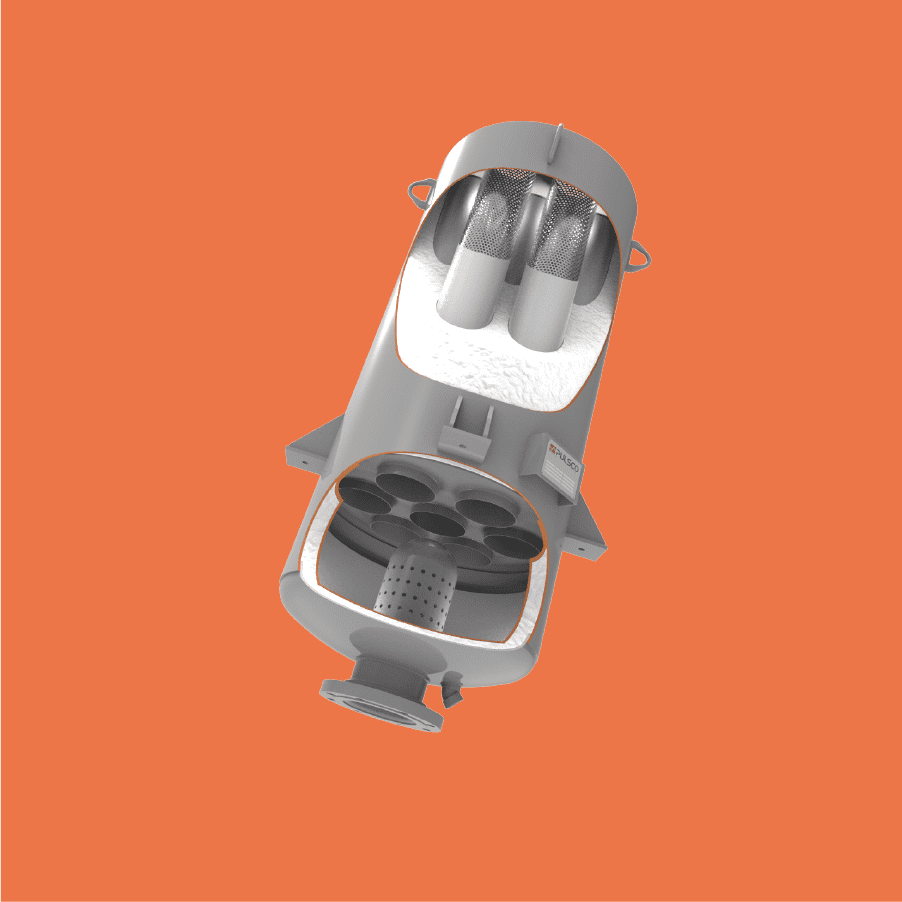

PULSCO is able to utilize a number of methods for attenuating noise.

Based on your inputs, we can optimally design a silencer to meet your requirements and specifications.

Cost of Ownership

Lastly, understanding the determining factors of the cost of ownership.

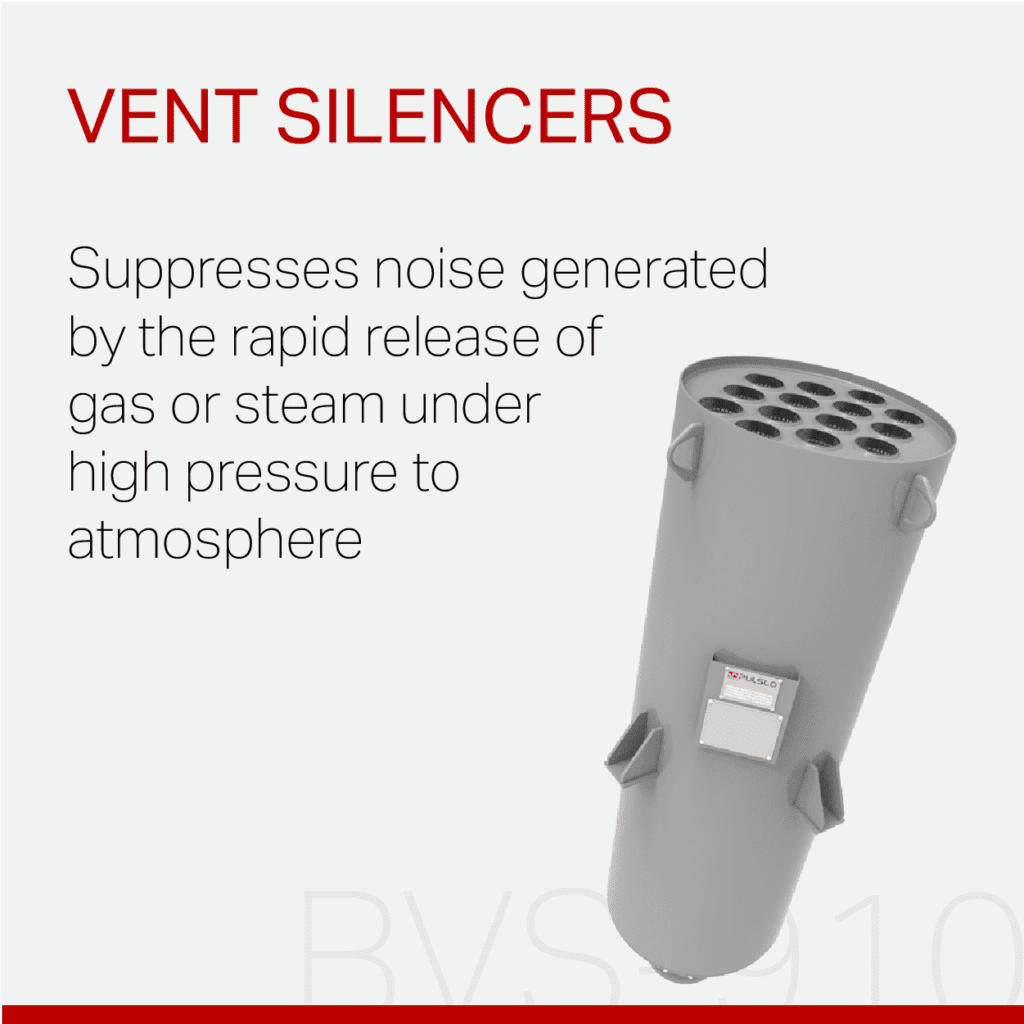

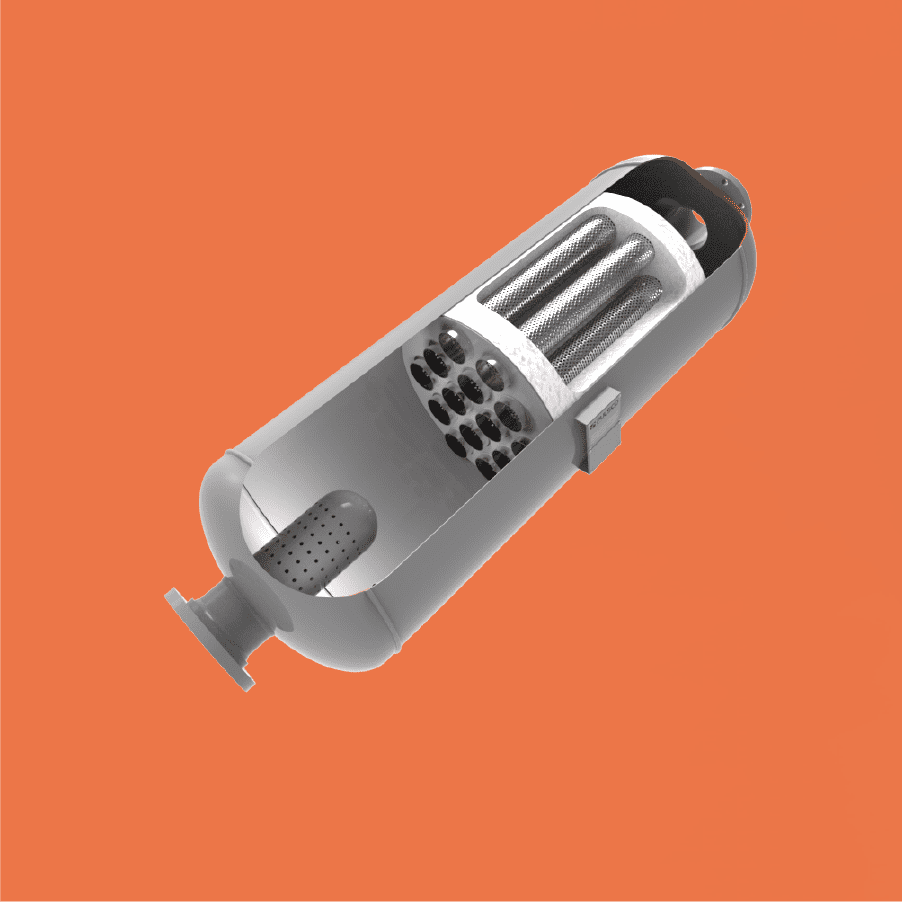

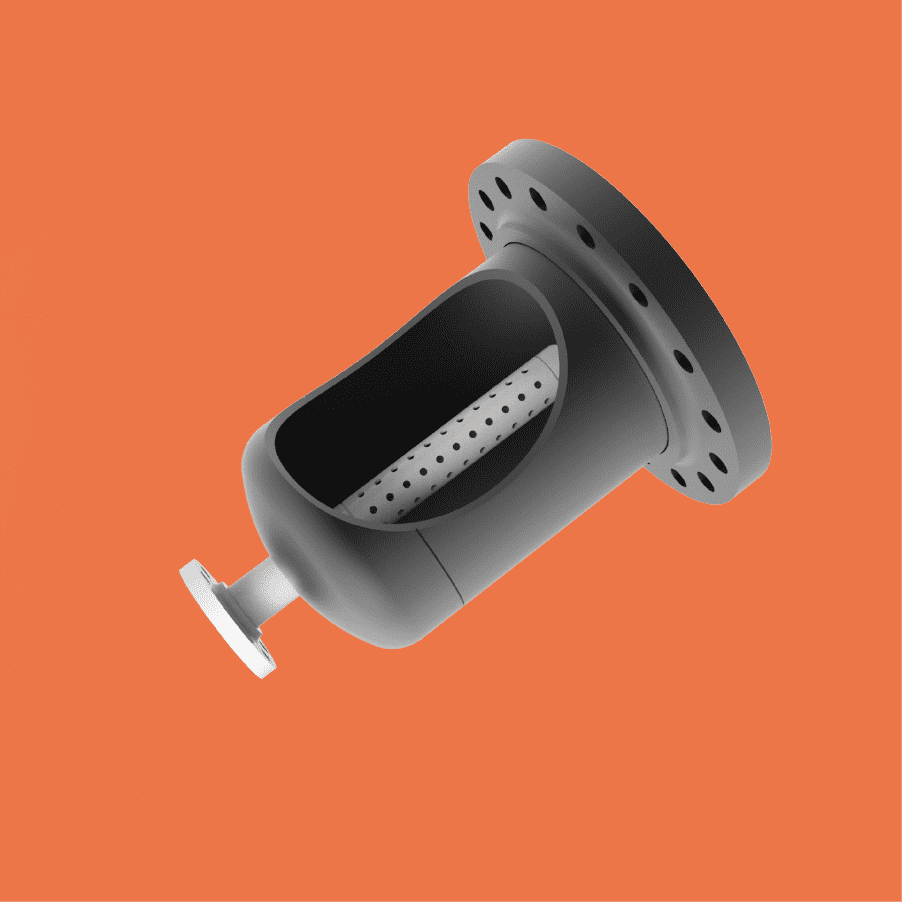

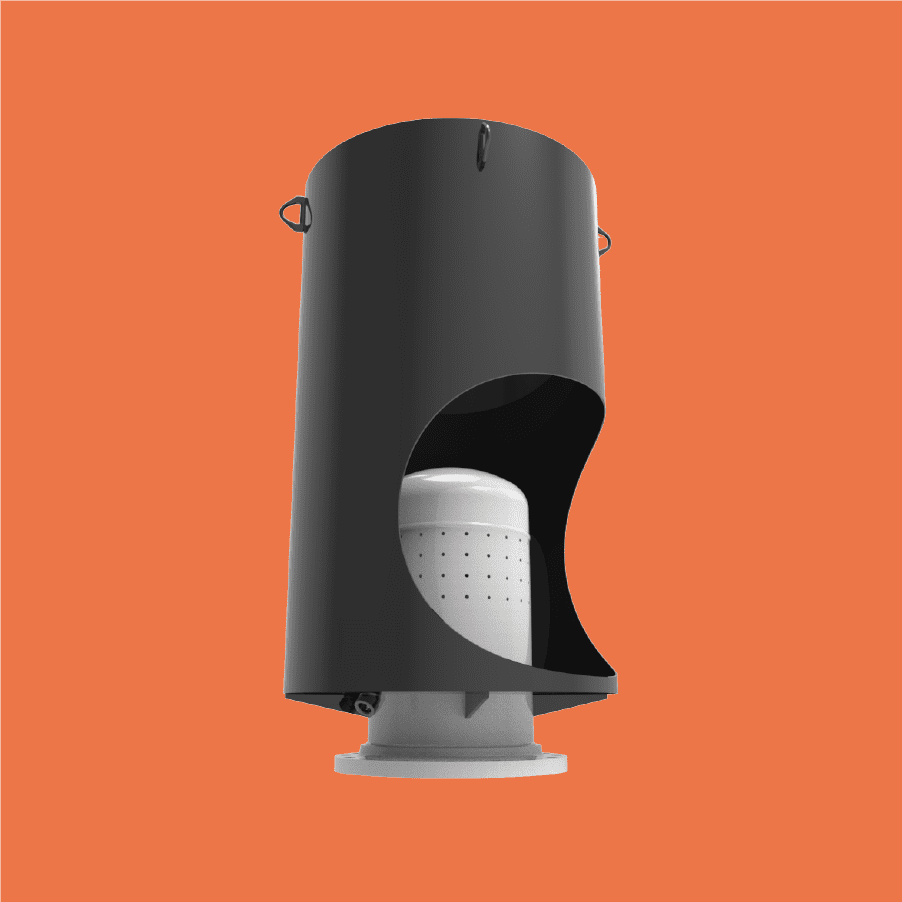

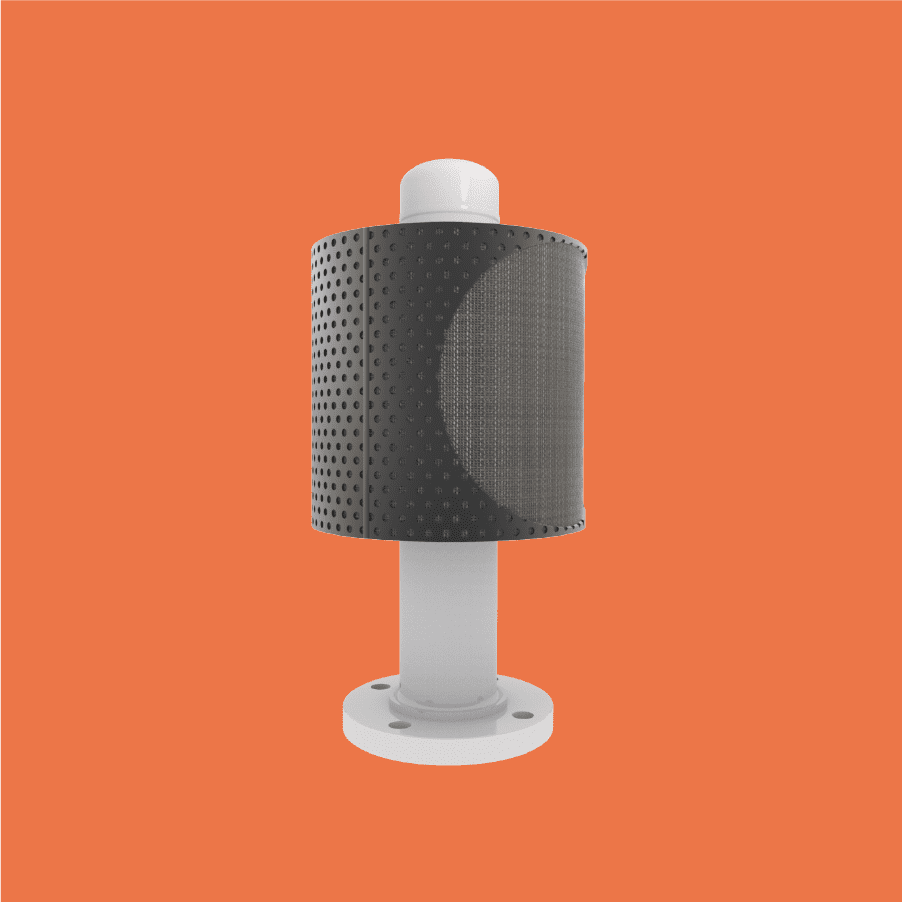

Noise Attenuating Solutions

How we differentiate the type of noise attenuation solution is based on the severity of the pressure relief.

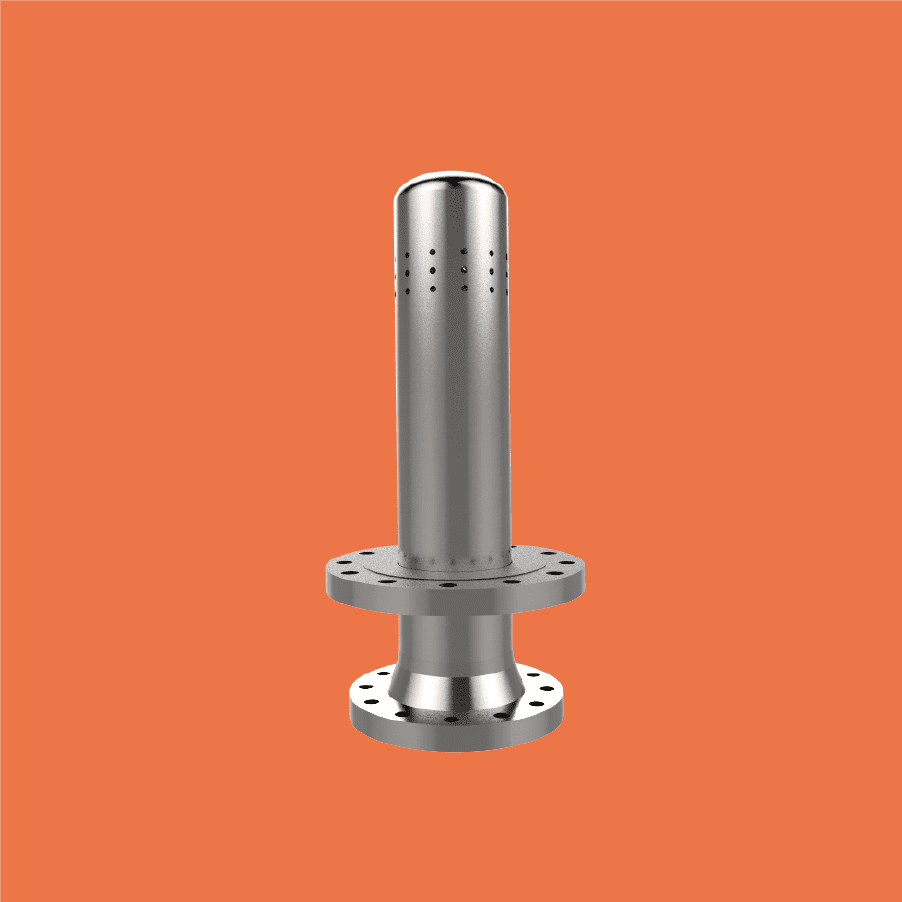

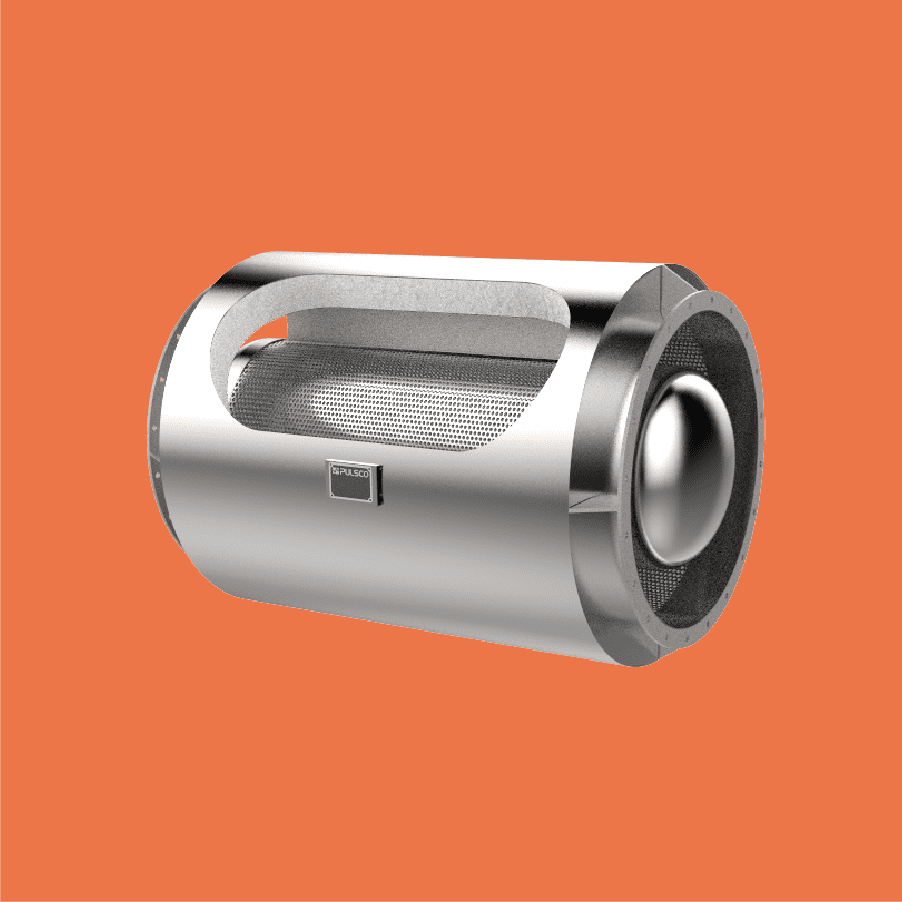

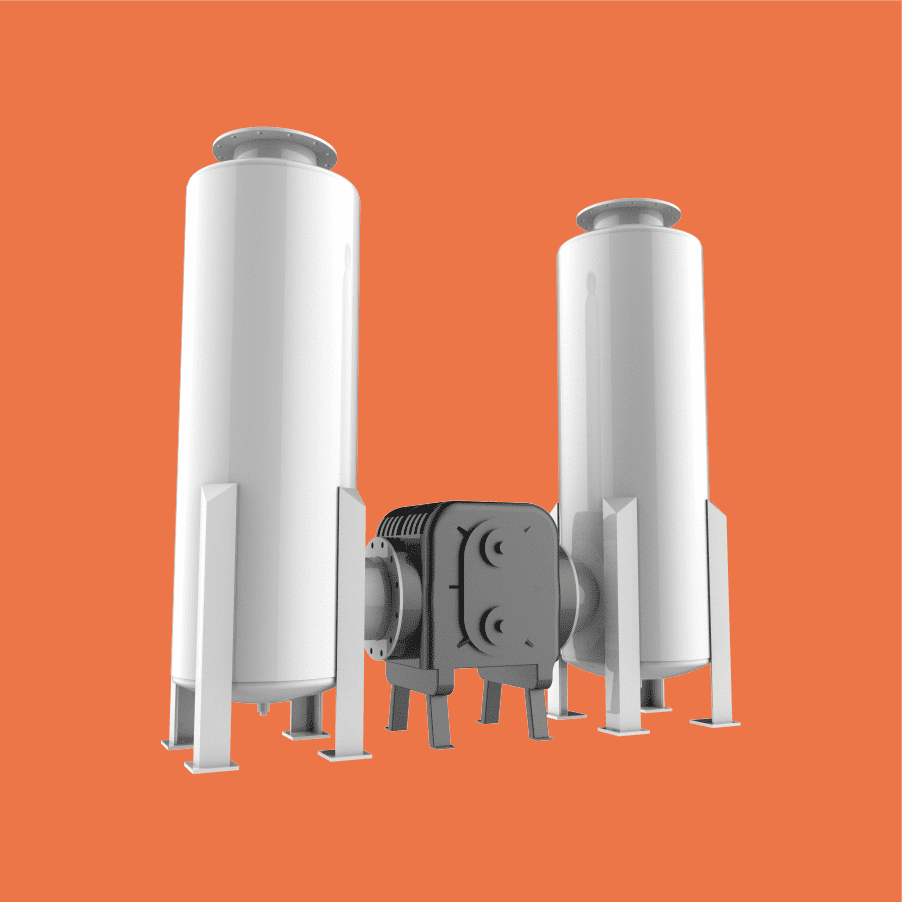

For high intensity, broadband noise associated with pressure relief systems and gas/steam line turbulence, PULSCO’s Blowdown Vent Silencers and Line Silencers provide the solution.

If a valve currently exists in the system, then PULSCO will match the silencer to the valve’s operating parameters.

Application

Valves

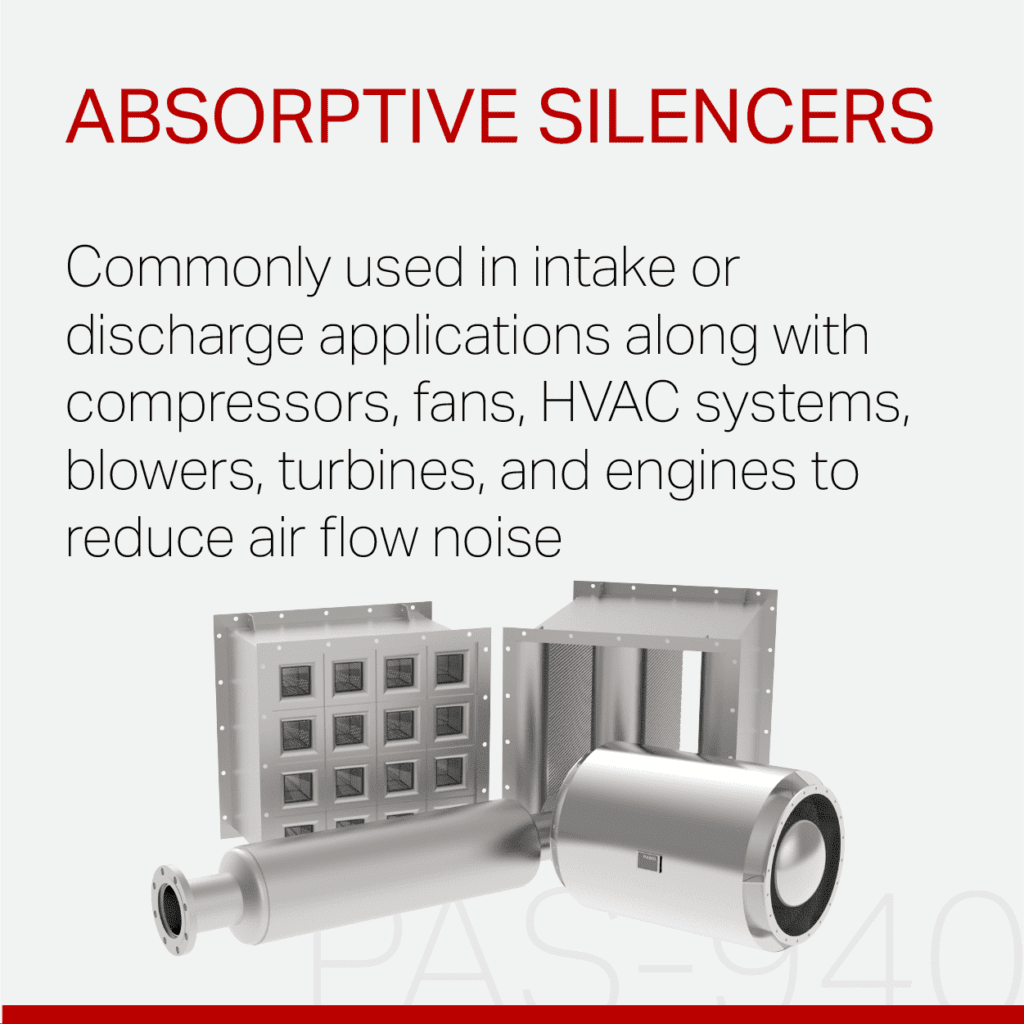

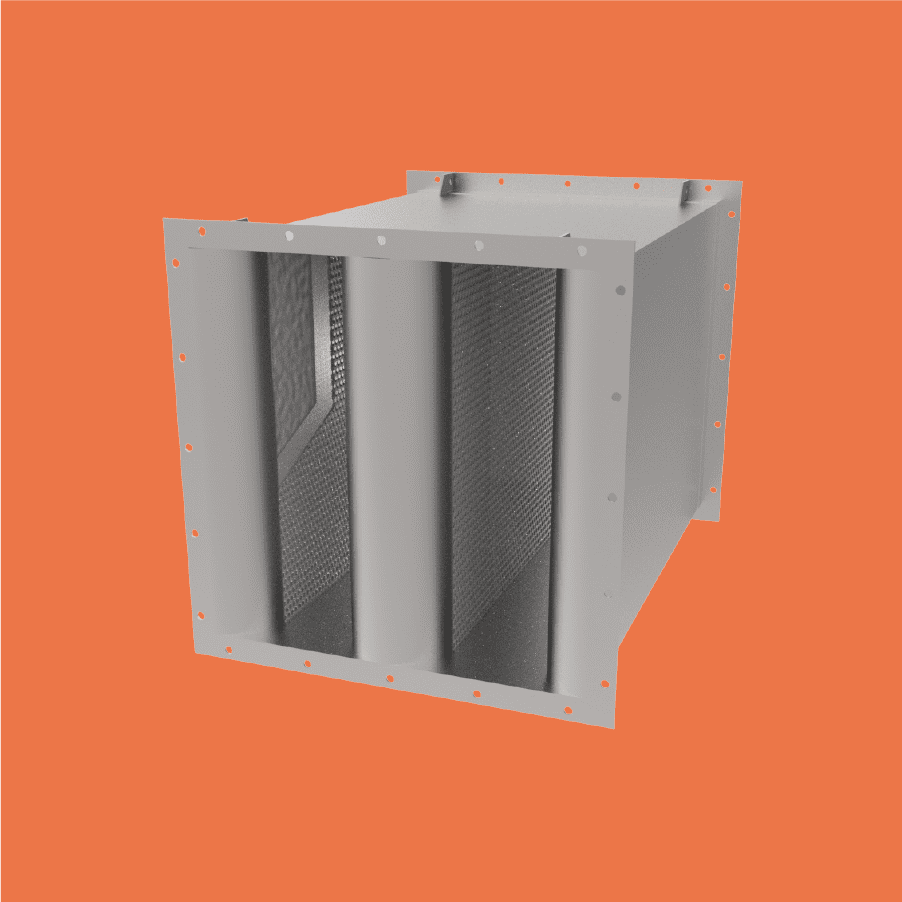

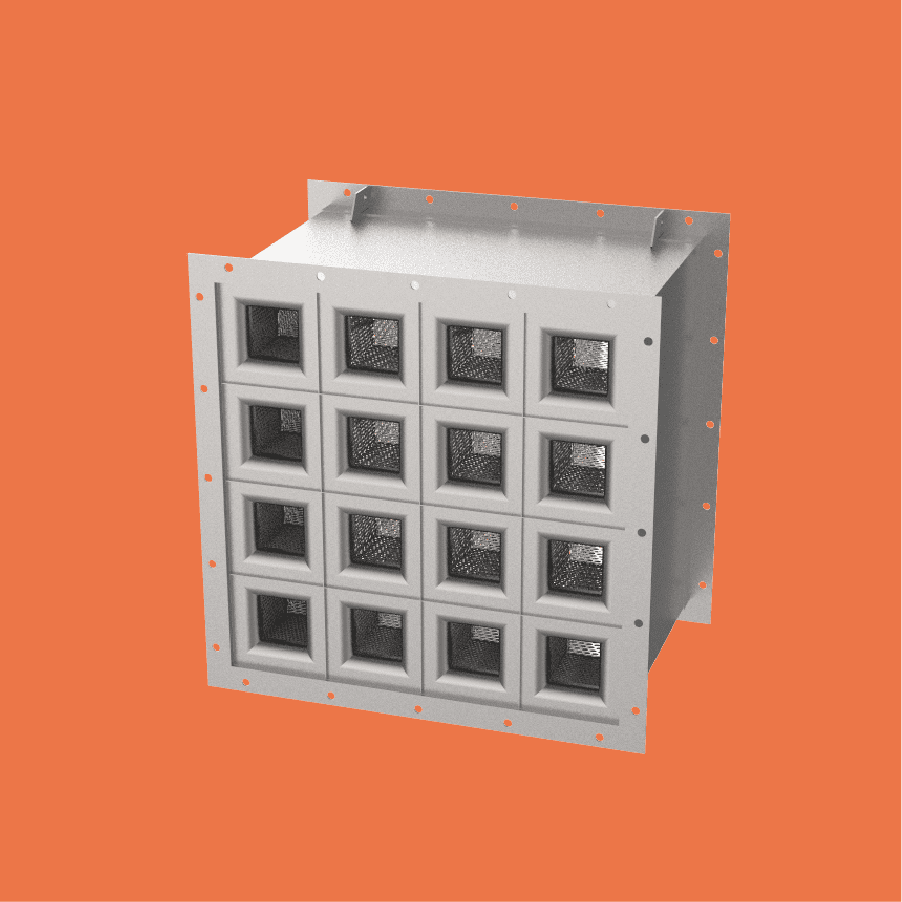

For lower pressure applications that require attenuation in the middle to high frequency range, PULSCO offers duct mutes with rectangular and tubular cross sections. Middle to high frequency application normally involves the following:

Compressors

Fans & Blowers

Pumps

Engines

Specifications

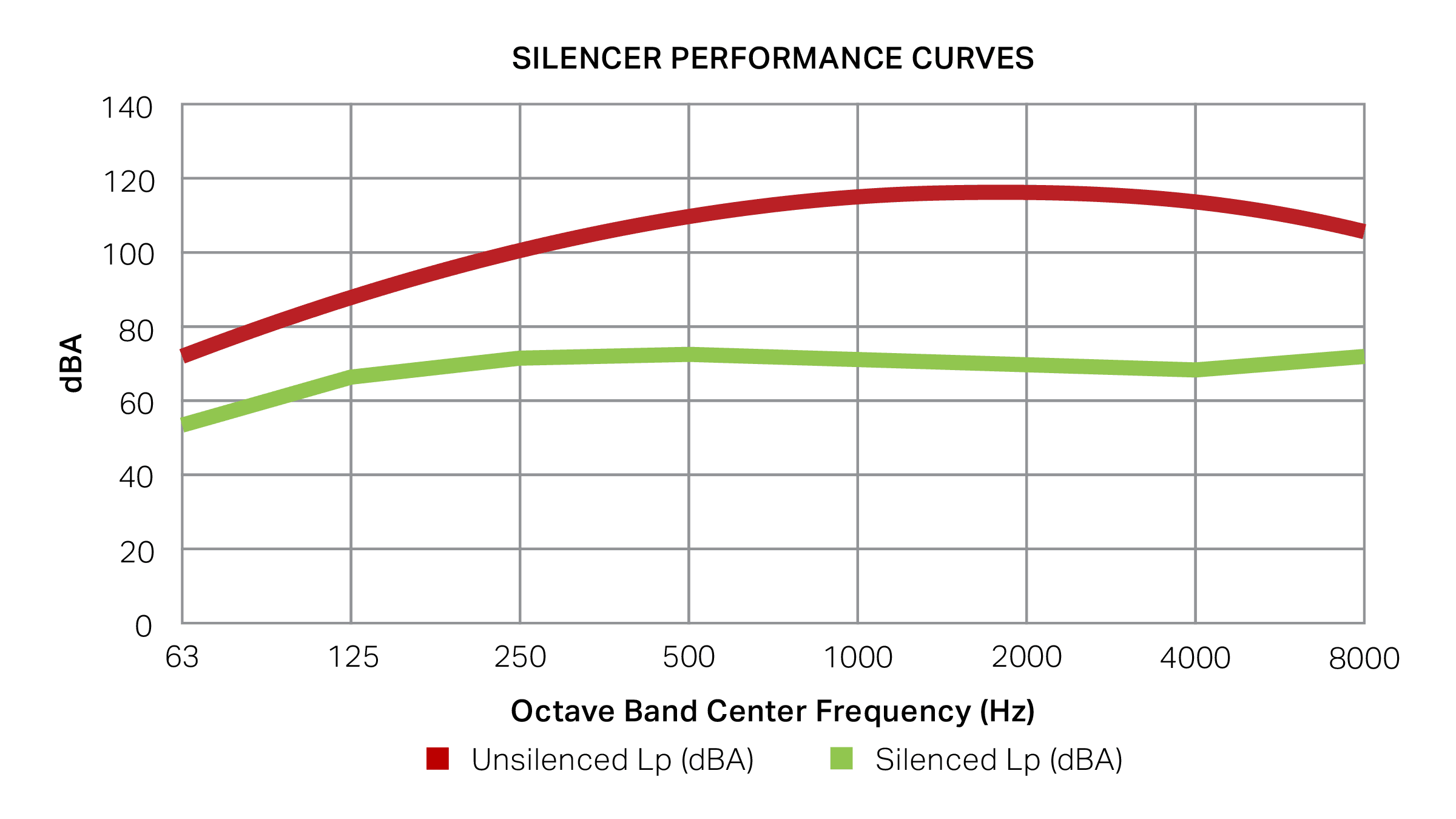

The PULSCO Silencer Sizing Program incorporates the customer’s operating conditions, specifications and system description to select the most cost effective silencer configuration.

Medium

What type of gas is flowing? Oxygen? Argon? Something else? The materials used to construct the silencer are dependent on the kind of medium we’re dealing with.

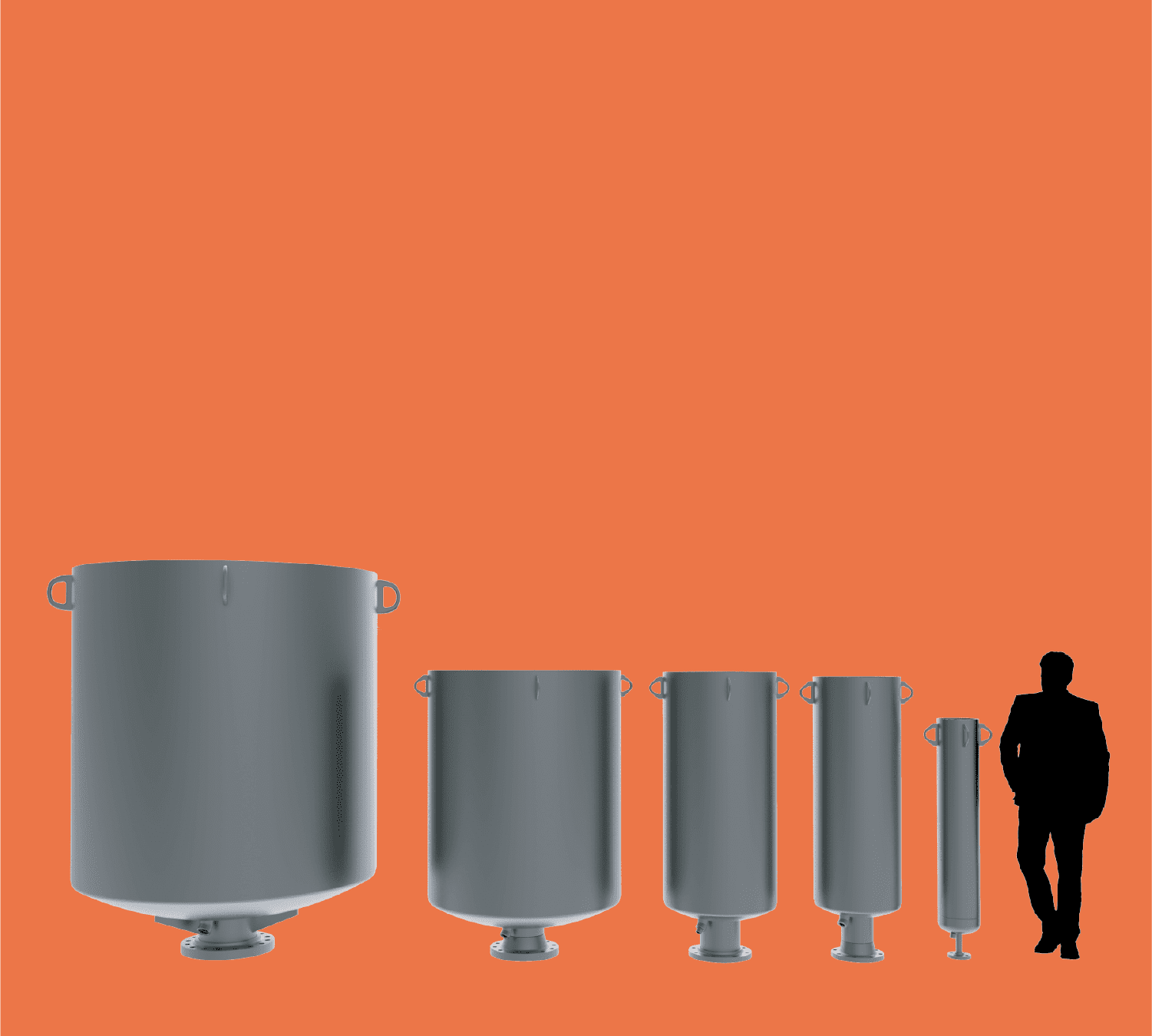

Volume/Flow

Sizing of the silencer is directly correlated to the flow of the gas through the silencer. The higher the flow rate, the larger the diameter of the silencer.

Temperature

The temperature of the medium is a factor in determining which materials we use to construct the silencer.

Pressure

PULSCO Vent and Silencers can provide a high range of pressure drops to your system. If paired with a valve, our silencers can provide a back pressure on the valve to optimize performance by reducing the pressure drop across the valve ultimately reducing the noise generated.

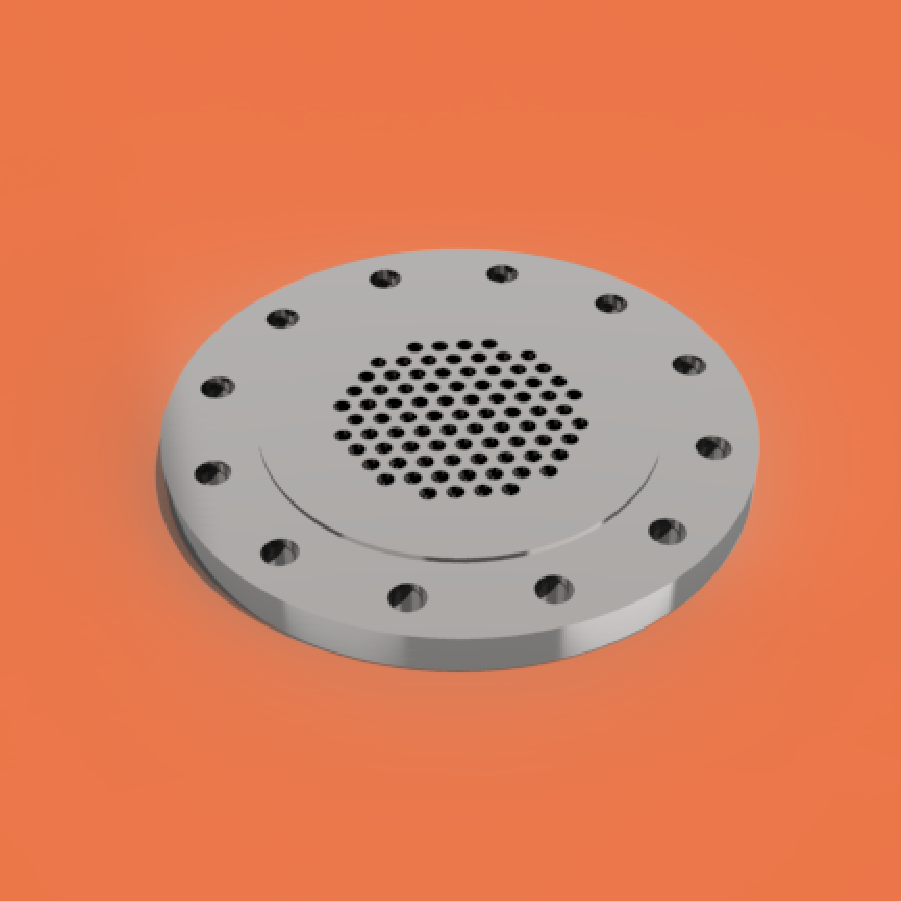

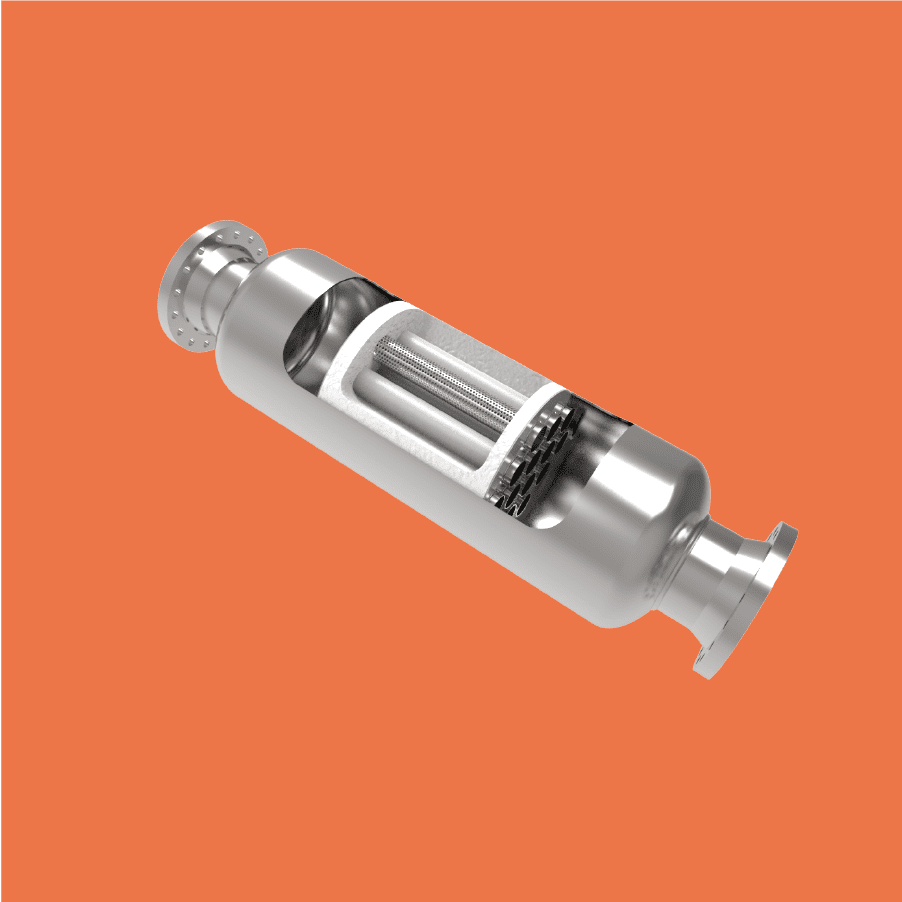

ASME, PED, CRN

All of PULSCO Line Silencers are ASME certified pressure vessels as a standard. Canadian Registration Number (CRN) and Pressure Equipment Directive (PED) certification can be provided upon request.

PULSCO’s experience and modeling tools allow accurate predictions of both the generated noise and the amount of attenuation to precisely size the silencer to a given amount of pressure relief.

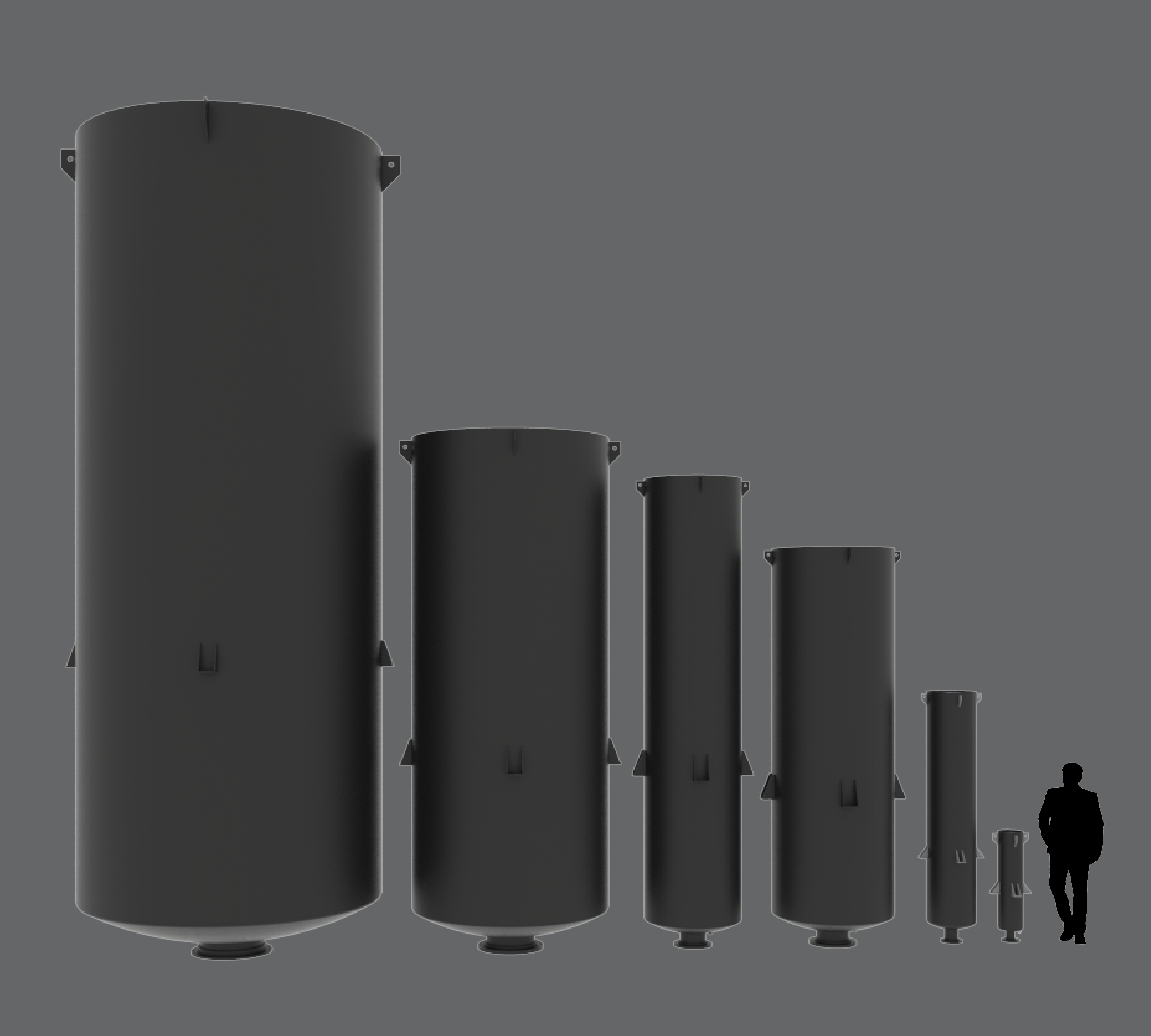

Silencer Sizing

The overall size of a silencer is dictated by the required the noise reduction and the flow rate of the particular gas. Noise reduction depends on the silencer’s length while the diameter of the silencer depends on the gas flow rate.

Silencer Materials

Silencer components are generally constructed from carbon steel. However, they may be constructed from other materials to meet specific design or application requirements such as high temperature, corrosive environment, or oxygen service. Material recommendations are dependent on the specified operating conditions.

Silencer Cost of Ownership

A fully-customized silencer optimized for performance will save your business time, manpower, and money in the long run.

Increased Valve Life

PULSCO Vent and Line Silencers are designed and engineered as a system, specifically matched to a control valve system to reduce the overall cost for the valve and silencer package and ultimately optimizing the performance of your factory.

Business Continuity

The unmatched reliability of PULSCO silencers prevent catastrophic occurrences that would interrupt production, shut plants down or other outages. Our reliable silencers ensure the continued productivity of your factory.

Decreased Capital Expenditure

The long-lasting durability of our silencers take more time to deteriorate than most silencers, reducing the amount of capital spent to replace or repair the equipment.