Call us 949.261.1717

For any question or concern

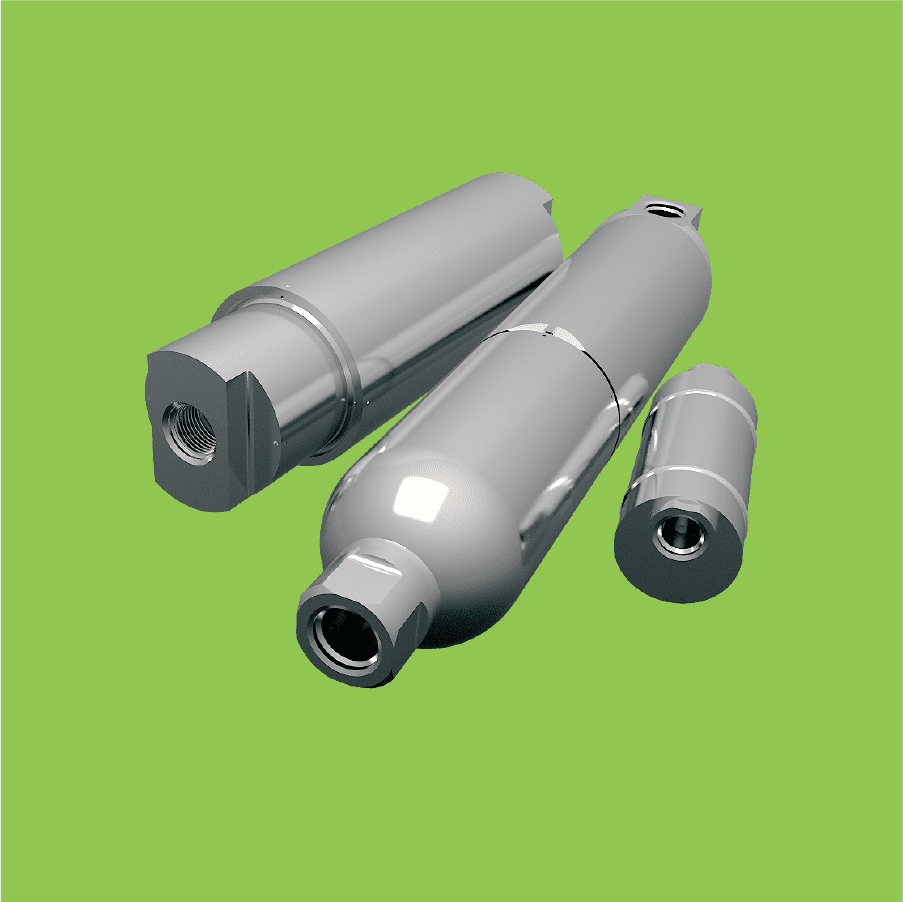

PULSCO’s Dampeners reduce piping and component deterioration and provide a quieter environment.

With a 90%-95% reduction in pressure pulsations over a wide frequency range with fluid-borne noise reduction of greater than 20 decibels. Attenuation is maintained throughout the system flow range, including zero flow and minimum pressure drop.

FAA Repair Station

PULSCO is approved to inspect, repair, and overhaul OEM components per Operational Specifications.

Product Exchange Program

PULSCO’s Product Exchange Program allows you to get your aircraft repaired and flying, without waiting for a part to be serviced or tested.

Design

PULSCO Liquid Dampener can be designed using a variety of materials to compensate for temperature, pressure, and flow conditions.

PULSCO’s experience and modeling tools allow accurate predictions of both the generated pressure pulse/noise and the amount of attenuation to precisely size the dampener to a given amount of pressure pulsation. The dampeners can be sized to handle a wide range of pulsation frequencies and flow rates. The diameter and length, as well as the inlet and outlet configuration can be varied to meet specific installation situations. They can be designed to meet a variety of industrial codes including PED, ASME, API, and ANSI. Units, ranging in size from 1.75 to 2.75 inches in diameter and 4 to 13 inches in length have been developed.

The most prevalent style used by PULSCO for higher frequency hydraulic systems is the three-chamber device. This design features a chamber divided into three compartments connected by series and branch tubes. The specific design, however, is dependent on the unique application and desired attenuation.

There is no gas charge to maintain or bladder to replace, and with no moving parts maintenance is minimal.

Application

Several of our designs have over 35 years of operational experience. A significant application has been on commercial and military aircraft. Systems we have produced pulsation dampeners for include:

Aircraft and Aircraft Engines – commercial and military, fixed and rotor wing

Marine Vessels – submarines and defense

Any place hydraulic fluids are pumped at high pressure

These units have reduced noise for increased passenger comfort and have diminished fluid line pressure pulsations, which have a negative impact on hydraulic system components. Units developed for aircraft have been instrumental in improving the operational characteristics of flight control surfaces.