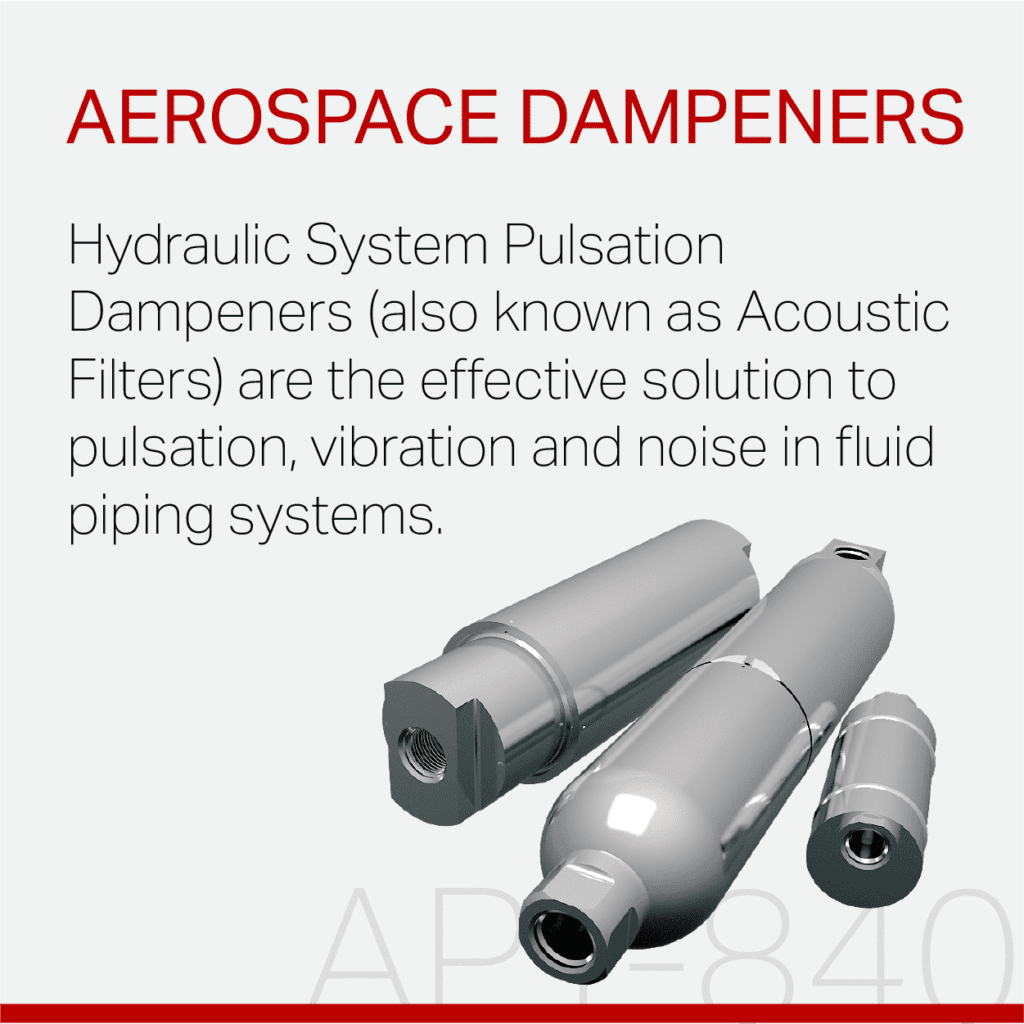

PULSCO was the first to develop gas and liquid pulsation dampener control equipment that utilizes acoustic theory and techniques to reduce noise and vibration.

For over 50 years, PULSCO has used state-of-the-art design methods to thoroughly analyze compressor and piping systems to protect our customers’ assets, keep them in business and optimize their performance.